Powercast Named a 2024 Best Place to Work

Powercast was chosen based on employee questionnaires that recognized the company’s intertwining environment, culture, and support of its employees in everything they do, from how they  interact with clients, to the sustainable wireless power solutions that they work to provide the world.

interact with clients, to the sustainable wireless power solutions that they work to provide the world.

Powercast has been named a 2024 Best Place to Work by Business Intelligence Group. This prestigious award highlights the company’s unwavering commitment to cultivating a workplace culture that prioritizes employee well-being, growth, and satisfaction.

Powercast was chosen based on employee questionnaires that recognized the company’s intertwining environment, culture, and support of its employees in everything they do, from how they interact with clients, to the sustainable wireless power solutions that they work to provide the world.

“We are honored to receive the Best Place to Work award,” said Charles Greene, Chief Operating & Technical Officer. “At Powercast, we recognize that our employees are our greatest asset, and this recognition is a reflection of their hard work, dedication, and commitment to Powercast’s shared values. We strive to create a positive workplace culture and believe it is the foundation for success, and we are proud to provide our employees an environment where they are encouraged to grow, innovate, and thrive.”

Greene continued, “One of the most important values at Powercast is the ability to offer our employees work-life balance and flexibility. We recognize the importance of supporting employees in both their professional and personal lives, and prioritize employee satisfaction and well-being. As Powercast celebrates this achievement, we remain committed to upholding our core values and providing a culture that recognizes and rewards outstanding contributions while we continue to build a team with an outstanding track record of success.”

Powercast Demonstrates Broad Applications of Wireless Power at CES 2024, Powering Environmentally-Friendly Products Short to Long Range & Microwatts to Kilowatts

Industry leader in far-field, over-the-air RF charging can now power products over entire spectrum of wireless power after expanding portfolio with near-field, contact-based inductive charging via partnership with Powermat.

Powercast, the industry’s complete solution for wireless power, providing short to long range and microwatts to kilowatts, will demonstrate at CES 2024, booth #51516, the breadth of solutions it can provide via its expanded portfolio. Powercast expanded its portfolio via a partnership with Powermat in 2023 to add Powermat’s short-range, high-power SmartInductiveTM hybrid inductive/resonance technology, best known for the smartphone charging surfaces deployed worldwide in cars and coffee shops, to its own award-winning long-distance, low-power radio-frequency (RF) technology.

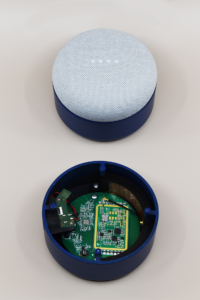

Google Home

These two pioneers of wireless power partnered to create one team that can implement sustainable, environmentally-friendly products across the entire spectrum of wireless power that can save manufacturers time and money, and cut wires and batteries to eliminate clutter and curtail e-waste, saving hundreds of millions of batteries from landfills.

“We’ve had a record year and with the addition of Powermat’s SmartInductive technology, we’re prepared to meet growing demand for both the near and far-field segments of the wireless power market, which Research and Markets expects to reach $45.3 billion by 2030,” said Charles Greene, PhD, COO and CTO of Powercast. “The partnership has created a cohesive entity that saves customers from having to research power solutions, because no matter the application, our team can apply the best solution. Our expert engineering team can also support customers from concept to prototyping to production as needed. We are truly a wireless power one-stop-shop, which is a first-of-its kind convenience for customers.”

Wireless charger demos will include those featuring RF, SmartInductive and the technologies combined:

Through the Table SmartInductive Charger

- RFID RF chargers, designed to be the industry’s most economical RF chargers.

- SmartInductive “through-the-table” chargers that line up above/below and charge through a table up to 1.5 inches thick – no cutting or wires required.

- A dual-technology RF/SmartInductive charger jointly developed by Powercast and Powermat designed to charge phones placed directly on it, and RF-enabled devices placed near it. The range for over-the-air RF charging is about one to 15 feet, but ultra-low-power devices like sensors can charge up to 120 feet away.

- A retrofitted Google Home Nest that now also transmits RF power, demonstrating Powercast’s drop-in RFID module that lets manufacturers easily embed RF charging into their own devices for only a $5 bill-of-materials (BOM) cost.

Wireless products that these transmitters can charge will also be demonstrated:

- A retrofitted DeWalt power drill that recharges on a SmartInductive charging surface.

- The Dolphin Liberty cordless pool cleaning robot featuring SmartInductive, a technology that’s capable of underwater charging.

Drill

- A retrofitted Arlo security camera installed outside a home that recharges through the wall from an RF transmitter inside the home – eliminating the need to hire technicians and drill holes/run wires outside.

- A demo combining two small-form-factor technologies – Nichicon’s rechargeable batteries and Powercast’s PCC110 RF Powerharvester® chip – to create rechargeable, space-constrained devices such as styluses, medical devices and IoT sensors.

Arlo Camera

- And many other products including a keyboard and mouse, TV remote, charging grip for the Nintendo Joy-Cons, home security and IoT sensors, door lock, digital luggage tag, smart product packaging, and even Smartballs with sensors to deliver analytics for sports like cricket or football.

Optimized for different applications, Powercast’s and Powermat’s technologies differ in strength and transfer distance, and together cover the entire spectrum of wireless power:

- Powercast’s RF transmitters/receivers can transfer power up to 120 feet, but deliver lower levels: 100s of milliwatts to single-digit microwatts. This technology is suited for one-to-many charging of low-power devices, like IoT security and home automation sensors in remote locations where wiring/battery replacement is inconvenient or prohibitive, and other consumer devices like game controllers, wearables, headphones and other hearables, keyboards and mice, TV remotes and more.

TV Remote Control

- Powermat’s SmartInductive transmitting/receiving coils charge one product at a time and must closely align – within 8 inches – but can transfer more power: 5 watts for consumer-grade applications to 600 watts for industrial-grade ones like telecom, robotics, micro-mobility, medical and underwater charging.

Greene explained, “Our vision is a world where power is ubiquitous, sustainable, wire-free, and seamlessly accessible. Our ultimate goal is true wireless freedom through an ecosystem of connected transmitters and receivers, both in the public and private domains, which provide people, products and machines the ability to move around freely with seamless access to power.”

Nichicon Stylus

Discover a ground-breaking wireless technology interview with Charlie Greene in Easy Engineering Magazine