Powercast Corporation, the industry’s one-stop-shop for wireless power, announced it has joined RAIN RFID Alliance’s Sustainability Working Group. This group’s goal is to provide education  onhow RAIN RFID technology, already used worldwide for the item tracking necessary in inventory management, stock control, logistics, retail and other applications, can also be an enabler for companies to achieve their sustainability objectives.

onhow RAIN RFID technology, already used worldwide for the item tracking necessary in inventory management, stock control, logistics, retail and other applications, can also be an enabler for companies to achieve their sustainability objectives.

What is RAIN RFID? RAIN Radio Frequency Identification (RFID) is a wireless technology that uses both handheld and fixed ultra-high frequency (UHF) RFID inventory readers that are prevalent in industries around the globe to connect billions of everyday items to the internet. It enables businesses and consumers to identify, locate, authenticate and engage each item bearing an RFID tag or label.

The Sustainability Working Group just published a report, “Bridging the Gap – Connecting Corporate Sustainability with RAIN RFID,” based on a 20-company survey of apparel, automotive, healthcare and other companies. Findings include:

- Data collected in existing RFID applications can also inform sustainability strategies, and there is evidence this is happening, but more education is needed to bridge RFID systems and sustainability efforts.

- Many examples of how RFID can help address sustainability challenges already exist, including: 1) achieving inventory accuracy levels that reduce waste and keep excess goods out of landfills, 2) being able to anticipate the lifespan of a product to facilitate recycling and waste management, and 3) collecting environmental data related to CO2 reduction.

“Powercast is committed to initiatives furthering a brighter sustainable future for generations to come, so we’re excited to join like-minded companies in RAIN’s Sustainability Working Group,” said Charles Greene, Ph.D., COO and CTO of Powercast. “Since 2007, our wireless power technologies have enabled untethered devices that need no battery maintenance and reduce the e-waste – cables, cords and disposable batteries – that litters landfills.”

Charles Goetz, CEO of Powercast, will explain wireless power’s role in sustainable RAIN RFID systems at the Connections Summit 2024, organized by RAIN RFID Alliance and NFC Forum, in Taichung, Taiwan, from May 13th to 16th.

“Combining RAIN’s identification and communication capabilities with Powercast’s radio frequency (RF) to direct current (DC) conversion technology can create smart, sustainable, maintenance-free device ecosystems able to both recharge and communicate over the air without wires or disposable batteries,” continued Greene.

How Powercast’s Wireless RF Power Technology Combines with RAIN RFID to Add Functionality:

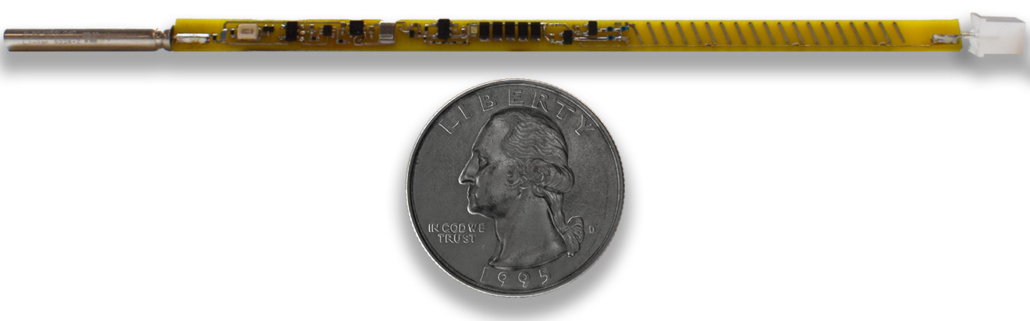

Since UHF RFID readers emit an RF signal that’s similar to that of Powercast’s RF wireless power transmitters, these readers can be a reliable source of wireless power. Powercast’s tiny Powerharvester® PCC110 receiver chip embedded in RFID tags or labels can harvest RF and data sent over the air from any RFID reader – whether it’s fixed infrastructure or a handheld reader used by employees – and convert that RF to usable DC to both power devices and communicate data. Range depends on power consumption level; most devices can function up to 20 feet from a reader, while ultra-low-power devices can work up to 120 feet away. Devices can either be batteryless or rechargeable-battery-based, which eliminates inconvenient and expensive battery replacement efforts and keeps disposable batteries out of landfills.

As examples, a Powerharvester embedded in an electronic paper display (EPD) tag such as a retail electronic shelf-edge label (ESL), or an environmental sensing or logistics tag can harvest RF when it comes within range of a UHF RFID reader.

Several EPD applications were recently developed using partner E Ink’s bi-stable digital ePaper screen that can maintain an image perpetually, without a constant power source, until another over-the-air wireless update is sent. These EPDs include a wireless electronic bag tag, which harvests RF from airport RFID equipment to refresh the passenger’s itinerary on the screen; and Powercast’s own batteryless ESL which enables over-the-air retail price updates.

Other RFID over-the-air wireless power applications include environmental monitoring, such as Powercast’s RFID Sensor Tags which measure temperature, light and humidity; logistics and advanced location tracking devices; and sensing devices on products such as tires.

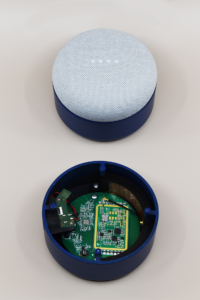

automation sensors. These sensors: 1) integrate into smart home ecosystems (Google Home, Amazon Alexa, Samsung SmartThings) using Matter, 2) easily install anywhere, 3) eliminate the need for expensive home wiring, 4) won’t require inconvenient, expensive battery maintenance, and 5) keep toxic disposable batteries out of landfills.

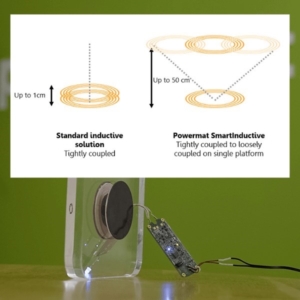

automation sensors. These sensors: 1) integrate into smart home ecosystems (Google Home, Amazon Alexa, Samsung SmartThings) using Matter, 2) easily install anywhere, 3) eliminate the need for expensive home wiring, 4) won’t require inconvenient, expensive battery maintenance, and 5) keep toxic disposable batteries out of landfills. One RF transmitter in a room can power sensors installed up to 25 feet away, so placing one transmitter in each room will create a wireless power network able to perpetually power all the RF-enabled sensors throughout the home. There are also options for RF transmitters, including a licensable reference design that lets manufacturers integrate the electronics needed to convert their household products into RFID RF transmitters for only $5 bill-of-material (BOM) cost.

One RF transmitter in a room can power sensors installed up to 25 feet away, so placing one transmitter in each room will create a wireless power network able to perpetually power all the RF-enabled sensors throughout the home. There are also options for RF transmitters, including a licensable reference design that lets manufacturers integrate the electronics needed to convert their household products into RFID RF transmitters for only $5 bill-of-material (BOM) cost.

onhow RAIN RFID technology, already used worldwide for the item tracking necessary in inventory management, stock control, logistics, retail and other applications, can also be an enabler for companies to achieve their sustainability objectives.

onhow RAIN RFID technology, already used worldwide for the item tracking necessary in inventory management, stock control, logistics, retail and other applications, can also be an enabler for companies to achieve their sustainability objectives. The Wireless 25-Year Maintenance-Free Building Automation Sensor and Controller Technology for HVAC, Lighting Saves Substantial Energy, Costs 40% Less than Wired Systems, Eliminates Battery Maintenance and Reduces Battery E-Waste

The Wireless 25-Year Maintenance-Free Building Automation Sensor and Controller Technology for HVAC, Lighting Saves Substantial Energy, Costs 40% Less than Wired Systems, Eliminates Battery Maintenance and Reduces Battery E-Waste interact with clients, to the sustainable wireless power solutions that they work to provide the world.

interact with clients, to the sustainable wireless power solutions that they work to provide the world.

or none at all.

or none at all. like telecom, robotics, micro-mobility, medical devices, and underwater charging.

like telecom, robotics, micro-mobility, medical devices, and underwater charging.